Behind the Scenes: The Making of Tesla's Gigafactories

The Tesla Gigafactories are not just manufacturing sites; they are monuments to innovation and sustainability, reshaping the landscape of electric vehicle production. As we delve into the making of Tesla Gigafactories, it's essential to understand the multifaceted approach Tesla takes—from conceptualization to execution—encompassing Tesla manufacturing processes, supply chain management, and the integration of renewable energy in manufacturing.

The Genesis of Tesla Gigafactories

The story of Tesla Gigafactories begins with a visionary goal set by Elon Musk to accelerate the world's transition to sustainable energy. The term 'Gigafactory' stems from 'giga,' a unit of measurement that signifies billions, which represents the factory’s production capacity, not just in terms of physical size but output. The primary purpose of these gargantuan facilities is to streamline Tesla’s manufacturing process and ensure a steady supply of lithium-ion batteries, which are crucial for sustainable vehicle production.

Strategic Gigafactory Locations

Strategic Locations and Innovative Design

Strategically located across the globe, each Gigafactory serves a dual purpose: optimizing Tesla’s supply chain and minimizing environmental impact. For instance, the Nevada Gigafactory is strategically positioned to harness abundant solar energy, aligning with the goal of renewable energy in manufacturing. Similarly, the choice of Shanghai for one of the Gigafactories taps into China’s vast market and its supply chain efficiencies, although it's worth noting that competitors like China’s BYD are rapidly catching up in electric vehicle sales (source).

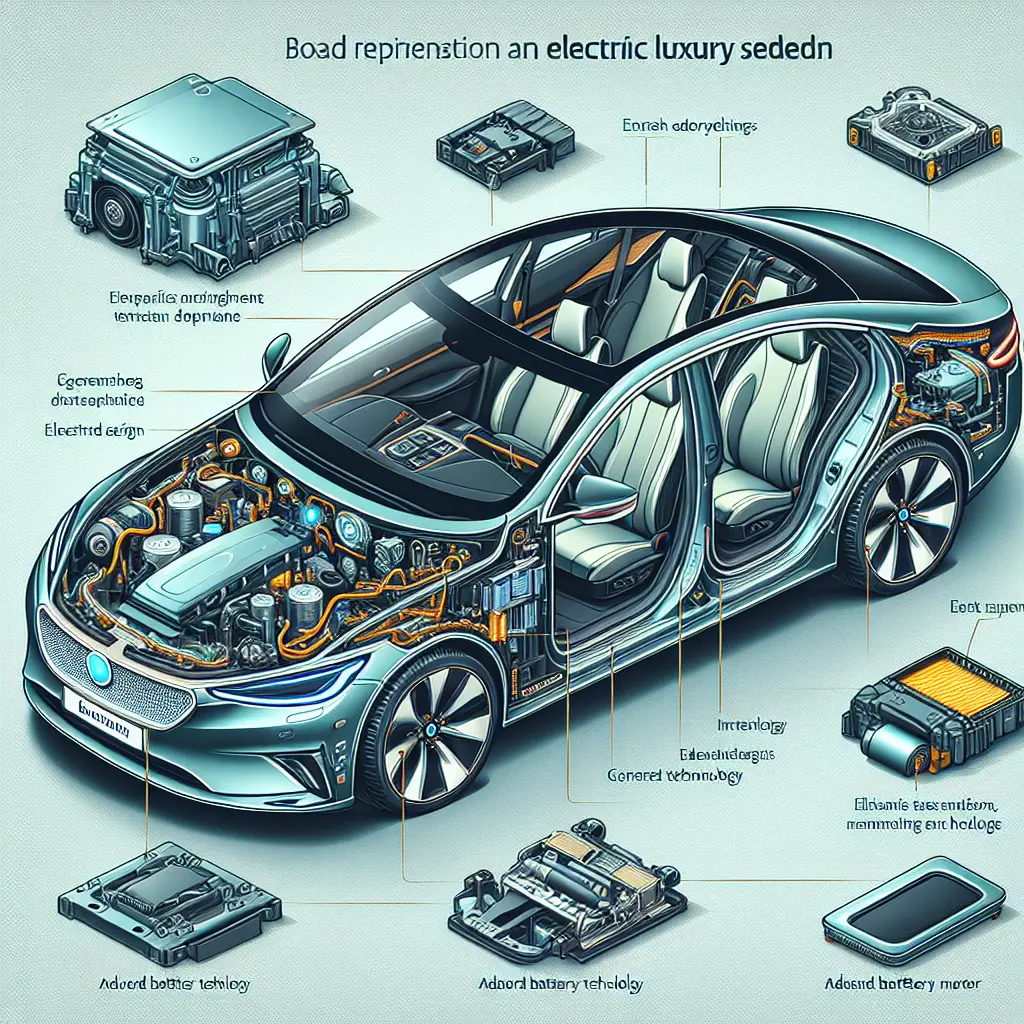

Tesla factory design is a testament to Elon Musk's commitment to innovation and efficiency. Each Gigafactory is designed to house all aspects of production under one roof—battery production, vehicle assembly, and part manufacturing. This not only reduces logistical costs but also minimizes carbon footprint, making it a cornerstone of eco-friendly manufacturing.

Tesla Manufacturing Process and Automation Technology

At the heart of the Tesla manufacturing process is cutting-edge automation technology. The use of advanced robotics and artificial intelligence in Gigafactories enables precise and efficient manufacturing processes, reducing human error and enhancing safety. This high degree of automation allows for the rapid scaling of production capabilities essential for meeting growing global demand for electric vehicles.

Battery Production and Sustainability

Battery Production at the Gigafactory

Battery production is pivotal in the making of Tesla Gigafactories. The Nevada Gigafactory, in particular, is central to Tesla’s strategy for battery production. It aims to reduce battery costs through economies of scale and innovative manufacturing techniques, which is crucial for making electric vehicles affordable and mainstream.

Sustainability is woven into every aspect of the Gigafactories. From using renewable energy sources to power operations to recycling old batteries, Tesla ensures that its manufacturing process is as green as possible. This commitment extends beyond the factories themselves; it influences how Tesla designs its vehicles and chooses its materials.

Challenges and Criticisms

Despite these advancements, Tesla has faced its fair share of challenges and criticisms. Recent news highlights Elon Musk's controversial political endorsements and its potential risk to Tesla’s brand image (source). Furthermore, delays in projects like the highly anticipated Tesla Robotaxi have raised concerns about Tesla's ability to meet its futuristic promises (source).

Future Prospects and Conclusion

Looking forward, Tesla plans to expand its Gigafactory network. New locations are being scouted to enhance global reach and production capacity. This expansion is not just about scaling up but also about leveraging local advantages, whether they be logistical, resource-based, or regulatory.

In conclusion, the making of Tesla Gigafactories is a dynamic and evolving story. It encapsulates a blend of ambitious engineering, strategic foresight, and a steadfast commitment to sustainability. As Tesla continues to innovate and expand, the impact of its Gigafactories will undoubtedly play a crucial role in shaping the future of electric vehicle production and sustainable manufacturing globally.

Thank you for joining me on this deep dive into the making of Tesla Gigafactories. As we look towards a more sustainable future, let's stay inspired by innovations that challenge the status quo and push us closer to a cleaner, greener planet.

Leave a Comment